野生动植物监测系统

1 引言野生动植物是生物多样性中不可或缺的重要组成部分,对维持生态平衡和人类社会的可持续发展起到关键作用。然而,由于环境破坏、人类活 ...

1、application background

The railway is the major artery of the national economy. The safety of railway transportation not only affects the efficiency and efficiency of the railway itself, but also directly affects the production, life and stability of the entire society. Railway freight transportation is an important part of railway transportation. The purpose of railway goods is to safely and quickly deliver the goods to their destination. During the process of railway freight transportation, it is timely to discover abnormal problems such as over-limitation, over-bias, overload, etc. The detection of vehicles that are overloaded with over-constraint cargoes is of great significance for ensuring the safety of traffic and is one of the powerful measures to ensure safe driving. The abnormal loading of goods is an important cause of railway transportation accidents. Therefore, the real-time dynamic monitoring of loading status of trucks is an important means to ensure the safe operation of trucks. At present, in the cargo safety management, domestic railways still rely mainly on manual operations for abnormal loading of goods. That is, under the condition that the truck is stationary, the loading width and height can be measured by using a benchmark or a sliding rule, sometimes only relying on experience. Not only is the detection method simple, the equipment is simple, the accuracy is poor, the efficiency is low, but the work intensity is high, the missed detection rate is high, and it is even more difficult to perform dynamic detection on the running truck.

At present, there are many problems with the current status of truck loading in China. With the continuous increase in the speed of railway freight trains, the loading quality of goods in trucks and the quality requirements of the vehicles themselves are getting higher and higher. However, due to the quality of truck loading, the transportation is endangered. Safe accidents also happen from time to time. We believe that the safety of railway freight transportation is mainly governed by two aspects. One is to eliminate potential safety hazards from the source of loading, and the other is to monitor the operation process dynamically. Therefore, the application of the truck overload limit and loading status detection system at the cargo inspection station has become a trend of development. With advanced scientific and technological means, it can quickly and dynamically monitor the loading status of the goods during the operation of the trucks. The personnel provided accurate pre-inspection information, reduced the labor intensity of the cargo inspectors, discovered and dealt with existing safety hazards in time, and ensured the safety of cargo transportation.

2、About The System

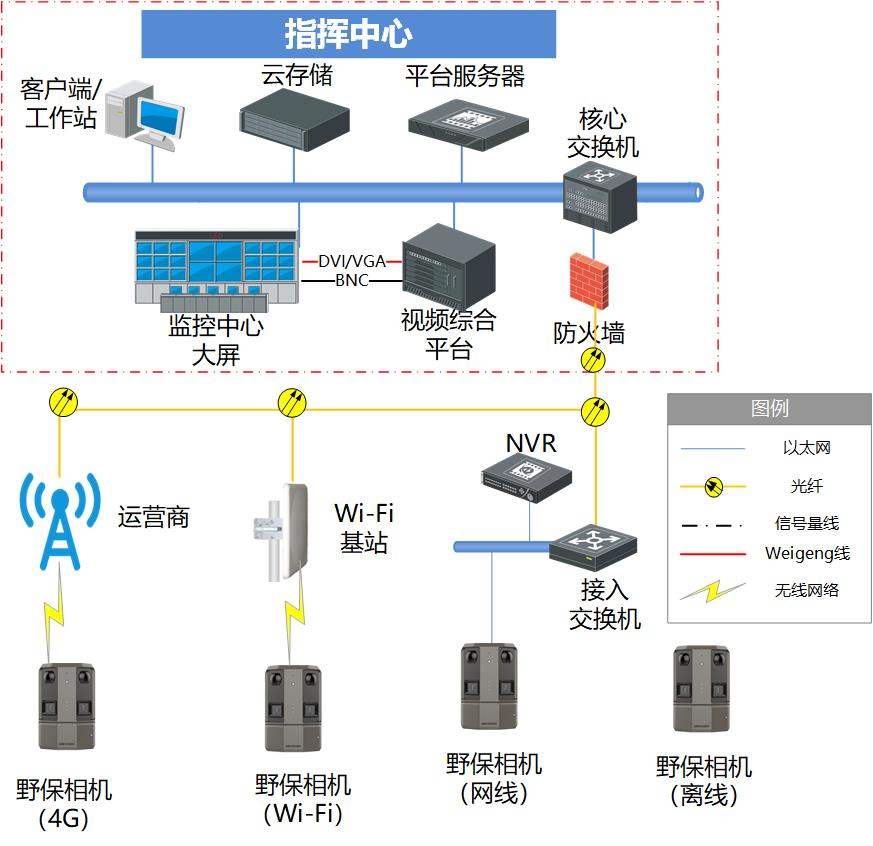

The high-definition video monitoring and early warning system of the loading state of railway wagons enables the real-time detection and determination of the running railway freight trains, and automatically recognizes, marks and alarms the abnormal (loading, placing) status of the goods in the carriage. It has the functions of super partial load monitoring, overrun detection, vehicle number identification, axle counting judgment, abnormal identification and alarm through cargo trains.

The system is equipped with real-time video surveillance and event recording, post-retrieval retrieval and video playback. It mainly completes the safety inspection of freight train loading status and provides powerful technical means for ensuring the safe production of railway freight trains.

The system is based on optical and electromechanical integration technology, automation control, video intelligent analysis and other technologies, and it has advanced into the vehicle number recognition system. After the front-end camera captures the video signal, it is transmitted to the remote monitoring center through the optical fiber. The inspector can see the high-definition scanning image when the truck passes the detection equipment, and automatically compares the loading status of the railroad truck with the intelligent image analysis software. Alarm prompts to realize the transition from manual inspection to automation. In the design of the system, based on the "rigorous, reasonable, reliable, economical, and perfect" design philosophy, the company strives to be safe, careful, and considerate of others, as a basis for providing advanced, safe, reliable, and efficient system solutions. .

3、Function Of The System

1 Acquisition function: Real-time collection of on-site train loading video information for system processing.

2 Transmission function: The collected video information is transmitted to the monitoring center of the station dispatching building in real time through the optical cable for monitoring and processing.

3 Pre-inspection function of cargo inspection: Multi-screen real-time monitoring of image and vehicle information on both sides of the truck can pre-check the train based on the surveillance video or playback video. The loading of the truck can be observed on both sides of the video and video. Status, security door status, etc.

4 Alarm function: If the vehicle safety door does not close properly, the system will automatically extract and voice alarm.

5 video playback function: can achieve four-screen synchronous playback, single-screen playback, slow release, fast playback, rewind, pause, segmented playback, single-frame playback and back, according to the specified number of car section play, zoom preview and Playback screen.

6 control function: enable the operator to realize the global control of the system without leaving the home.

3、Advantages Of The System

1 Reduce job risk and eliminate safety hazards

Traditional cargo inspection operations need to go to the site for on-site inspections. Trains need to be parked on the line, and a series of steps such as installation and installation of warning signs, notification dispatch, etc., are slightly inadvertent, and safety accidents can easily occur. Facts have proved that a considerable part of the safety incidents occurred during the inspection process. With this system, the cargo inspector can complete the cargo inspection indoors, and all the work can be done indoors without having to go to the site, eliminating potential safety hazards, ensuring safety, and at the same time reducing train stop time and further improving the railway Transport efficiency.

2 real-time slow playback, the most suitable real-time monitoring speed playback

Because the high-definition cargo inspection system can be used for shooting and monitoring under the condition that the truck passes through at a high speed, and the response speed of the human body to the image is limited, the system has added the function of setting the speed of real-time video playback. That is, after setting a predetermined playback speed, the cargo inspection personnel do not have to influence the quality of the inspection vehicle because the vehicle speed is too high, thereby realizing a high standard and high-accuracy operation quality. Under normal circumstances, the 22-inch widescreen monitor on the goods inspectors can be very good to complete the monitoring and inspection work, video images should be played at a speed of about 15 kilometers / hour, the equivalent of watching a row of 50 (C64K Gondola) trucks It takes about 3 minutes for our real-time slow release technology through our HD inspection.

3 Convenient control of high-definition color video to quickly locate problem vehicles

The system can not only realistically restore the train loading information, but the cargo inspectors can not only freely control the playback, fast forward, and slow release of high-definition color video, but also can perform zooming, panning, and other operations to further check the key suspicious parts once a suspicious vehicle is found. Greatly improved accuracy. At the same time, high-definition video also automatically divides the video according to the compartment, and the cargo inspector can quickly locate suspicious vehicles without having to repeatedly play videos to find vehicles. This is undoubtedly of great significance for improving the speed of inspection and improving efficiency.

4 Measuring cargo loading

The cargo inspection operation is inseparable from the measuring distance. The system has the functions of distance measuring tools and median line marking. Through measuring tools, distance measurement and other work can be completed on high-definition video. It is convenient, fast, accurate, and reduces the number of inspectors. The intensity of work also improves the safety of the measurement process.

1 引言野生动植物是生物多样性中不可或缺的重要组成部分,对维持生态平衡和人类社会的可持续发展起到关键作用。然而,由于环境破坏、人类活 ...

1 应用背景 当前中国经济的快速发展,石油天然气等能源产业在国家经济中的地位愈加显著。伴随着计算机技术、通信技术和视频技术的发展 ...

在我们赖以生存的地球上,森林成为人类繁衍生存必不可少的资源,目前全球的森林覆盖率为32 3%,森林资源在世界各地的分布也极不均匀。随着 ...

铁路是国民经济的大动脉,铁路运输安全不仅影响铁路本身的效率和效益,更直接影响了整个社会的生产生活和稳定和谐。铁路货物运输是铁 ...