野生动植物监测系统

1 引言野生动植物是生物多样性中不可或缺的重要组成部分,对维持生态平衡和人类社会的可持续发展起到关键作用。然而,由于环境破坏、人类活 ...

1、Application background

With the rapid development of China's economy, the oil and gas and other energy industries have become increasingly prominent in the national economy. With the development of computer technology, communication technology and video technology, the production monitoring system in the oil and gas industry has also made great progress. The realization of safe and efficient production, the implementation of remote digital management, effective control of the key technical links in the production process, and the reunification and coordination required for large-scale production are what many large-scale enterprises are currently looking forward to. The early security technology has been widely used in the production management and safety precautions of oilfield oil depots, overcoming the unfavorable factors such as geographical isolation, inconvenient transportation, geographical distribution, and lack of on-site manpower, and it is aimed at improving product performance and ease of use and reduction. Systemic costs and maintenance costs, and the enhancement of the safety of the working environment have also been updated.

Large-scale oilfield oil depots are usually located in areas far away from cities, sparsely populated swamps, deserts, basins, and shallow seas. Due to the characteristics of their working environment and nature, there are the following problems for control management and safety protection work in this field:

1. Oilfield oil depots are usually located in the outskirts, sparsely populated and have a wide area. Relatively few on-site duty stations and maintenance personnel are involved. The traditional way of working is usually based on the patrolling of staff in accordance with shift schedules. Each team usually has only one / two Personal, up to three people. In addition, due to the fact that the locations to be inspected are far apart from each other, and the special environment of oilfield oil depots does not allow vehicles to enter the area casually, and it is necessary for the staff to move on foot in the dicing area. Therefore, every two sites need a very long and twenty-minute road. Heavy workload.

On the one hand, there are problems such as low work efficiency and waste of manpower; on the other hand, hidden troubles such as illegal operation, mistakes in writing, and fraud are easily caused. As a result, the upper layer cannot correctly understand the actual situation on the spot and cannot use actual labor data consumed in production. , formulate more effective and flexible treatment programs.

2. The working environment of oilfield oil depots is highly dangerous. The general oil depot is divided into two types. One is a self-provided oil depot needed for oil field production. As a large-scale enterprise, each oil field consumes a large amount of oil daily and must have sufficient reserves; the other is a refined oil depot of oil refineries subordinate to oil fields. To store and refine the finished product oil. Oils are volatile and flammable gases. In addition, the oil, natural gas, and other resources involved in oil field operations are incalculable, regardless of the type. The consequences of the explosion and combustion caused by being ignited are inestimable.

Therefore, it is necessary to prevent three aspects of safety in the production process: First, the production and operation status of the working equipment itself, such as whether the oil tanks and valves in the reservoir area leak, whether the pipelines such as natural gas, kerosene, and petrochemical transmission burst or have been intentionally or unintentionally. The second is to supervise the compliance operations in the process of oil and oil delivery, such as supervising the vehicles entering and leaving the vehicle, recording the license plate numbers of vehicles entering and exiting, and supervising whether the staff violates regulations such as smoking, using lighters, etc.; third is the perimeter prevention alarm system. In order to prevent the intrusion of unrelated persons, theft and sabotage activities are carried out.

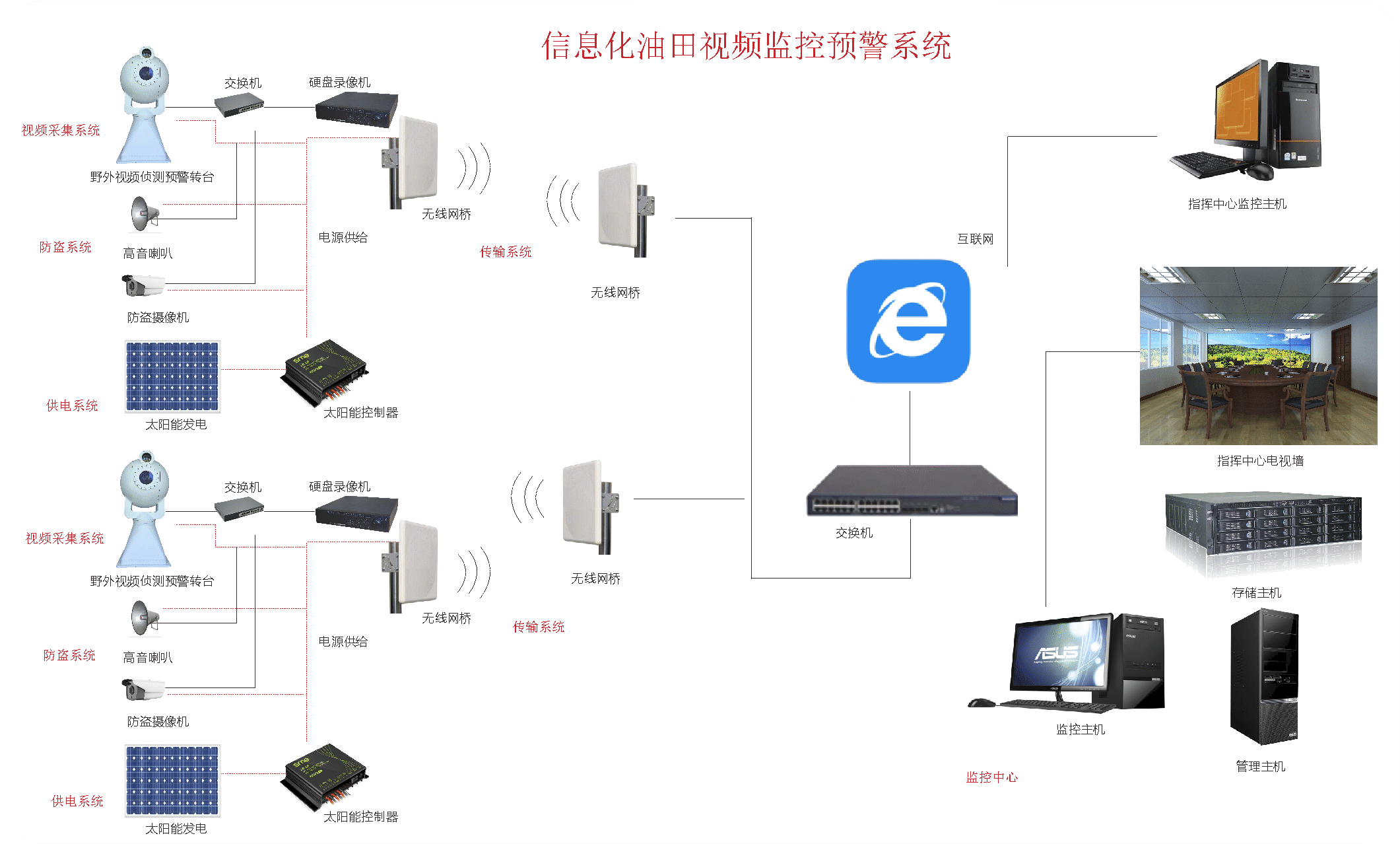

2、System composition

The oilfield video surveillance and early warning system consists of a front-end video acquisition system, a power supply system, an anti-theft system, a transmission system, and a back-end monitoring center. The schematic diagram of the system is as follows:

The key technologies of the oilfield video surveillance and early warning system are:

1The monitoring range is large;

2All-weather monitoring;

3 wireless transmission;

4 power supply system;

5 lightning protection grounding safety and reliability;

6 front-end equipment working status center monitoring.

Front-end video capture system

The front-end video acquisition system adopts the field video detection and warning turntable independently developed by our company. The turntable consists of a high-definition digital fog camera, a telephoto zoom lens, a forest fire special monitoring turntable, and a thermal imager. Using advanced far-infrared detection technology and applying infrared temperature measurement principle, it has two working modes: night imaging and visible light imaging. It can realize the effects of infrared and visible light imaging, and can work in dense smoke, heavy fog, night or bad weather conditions. , It can realize all-weather 24-hour monitoring of the forest area. The telephoto camera is controlled by a dedicated digital surveillance turntable at the front end. The camera can be positioned horizontally and horizontally by 0 or orm; 360360º, vertical -45º ++45º and the telephoto zoom lens can capture real-time video images within the monitoring range of the forest area and pass through the front end. The video processing module encodes and compresses the monitoring image data, transmits it to the monitoring center through the transmission system, and displays it on a large screen.

Transmission system

The transmission network is a necessary component for realizing the transmission of video images and various signals from the front-end base station of the oilfield video surveillance system to the back-end monitoring center. There are mainly two methods for the transmission network based on the oilfield video surveillance system. The first one uses the wired optical cable to carry out the Transmission, the second way to use wireless networks for transmission, for the distance or near the existing cable cable optical cable, when you can choose the transmission network, give priority to the use of wireless network transmission system, this is due to forest fire monitoring its own According to the characteristics, forest fire prevention monitoring and control bases are generally built in mountain areas. The geographical conditions and topography of different monitoring base stations are relatively complex. In the face of complex terrain, the use of wired optical cables is not only complicated to construct, but also the cost is very high. Destruction of vegetation is a way of destroying the environment and not economical. Wireless bridge transmission is the first choice for transmission links of forest fire prevention monitoring systems because of its advantages of simple construction, low cost, and one-time investment. The image is transmitted in real time, clear, and the transmission frequency is optional. The transmission distance can reach 30 kilometers. In the case of obstructions, the relay system can be set up.

Power supply system

The front-end equipment of the oilfield video monitoring system is generally located in the wild. The power supply of the monitoring point equipment is a very important link and an important prerequisite for ensuring the normal operation of the front-end base station equipment. In most cases, the field front-end base stations do not have mains access. The access points that access the mains are usually far away. Long-distance access to mains to the base stations not only results in very low voltages reaching the base stations and can cause damage to the equipment. Construction along the way can cause damage to the environment and the cost is very high. For the oilfield video surveillance front-end base stations, the use of solar power generation systems is preferred.

Back-end monitoring center

The back-end monitoring center is composed of a monitoring management platform, a splicing screen, and a decoder. Its main function is to obtain information, dynamic monitoring. Acquiring information: By using field front-end video monitoring points distributed at different heights, surveillance video information, meteorological information, and geographic information within the scope of monitoring are obtained to achieve all-weather uninterrupted monitoring. Dynamic monitoring: With the support of the transmission system, video images and other information are transmitted to the monitoring center in real time and synchronously to realize real-time observation of the dynamic conditions of the oil field.

1 引言野生动植物是生物多样性中不可或缺的重要组成部分,对维持生态平衡和人类社会的可持续发展起到关键作用。然而,由于环境破坏、人类活 ...

1 应用背景 当前中国经济的快速发展,石油天然气等能源产业在国家经济中的地位愈加显著。伴随着计算机技术、通信技术和视频技术的发展 ...

在我们赖以生存的地球上,森林成为人类繁衍生存必不可少的资源,目前全球的森林覆盖率为32 3%,森林资源在世界各地的分布也极不均匀。随着 ...

铁路是国民经济的大动脉,铁路运输安全不仅影响铁路本身的效率和效益,更直接影响了整个社会的生产生活和稳定和谐。铁路货物运输是铁 ...